Table of Contents

- Introduction to Honeycomb Panels

- Design Benefits of Honeycomb Panels

- Strength and Durability

- Lightweight Advantages in Modern Engineering

- Versatile Applications Across Industries

- Environmental Impact and Sustainability

- The Future Outlook for Honeycomb Panels

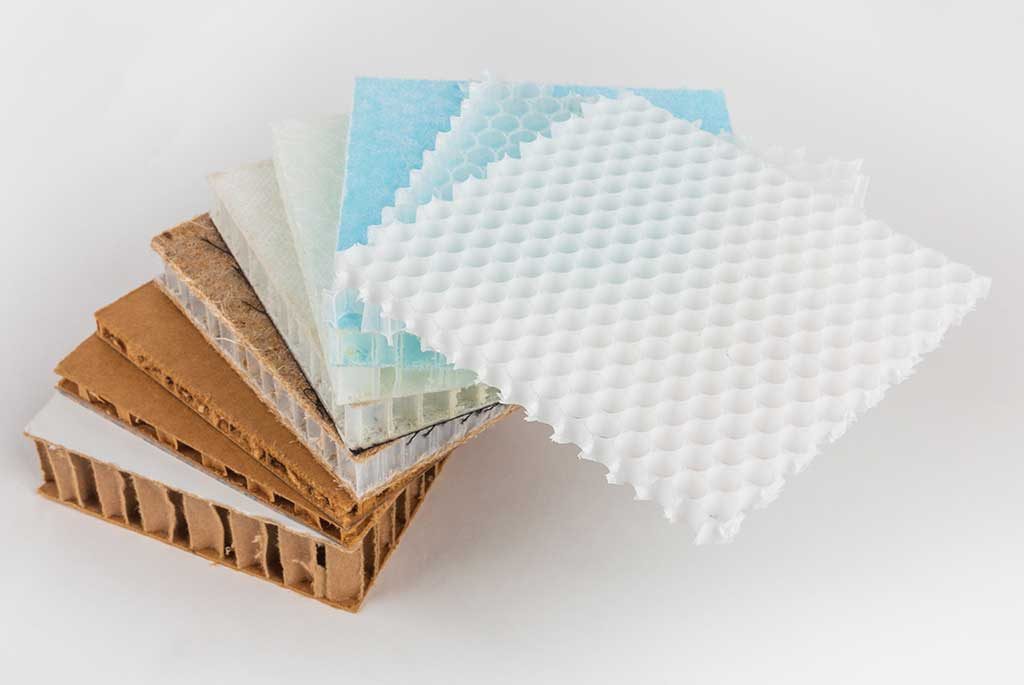

Introduction to Honeycomb Panels

In the rapidly evolving landscape of modern engineering, honeycomb panels have gained significant traction due to their unparalleled structural benefits. These panels draw inspiration from the efficient, hexagonal architecture found in nature, particularly bee hives, capturing the best design efficiency and natural ingenuity. This biomimicry offers significant enhancements in load-bearing capabilities without the additional weight traditionally associated with strength. They are particularly popular in applications where strength and weight reduction are critical components, as exemplified by their use in honeycomb sandwich panels Essex MA. This adoption speaks volumes about their versatility and effectiveness in diverse scenarios.

The appeal of honeycomb panels extends beyond their structural advantages. The inherent efficiency rooted in their design makes them a subject of fascination across various fields, from architecture to aerospace. Their natural mimicry not only represents an engineering marvel but also serves as a reminder of the simple yet profound complexity of nature’s creations. Thus, they are tangible proof of the potential for practical applications inspired by natural principles.

Design Benefits of Honeycomb Panels

Honeycomb panels are celebrated for their exceptional strength-to-weight ratio, positioning them as a favorite in fields that balance performance with economic viability. This ratio allows for meaningful reductions in material consumption while maintaining high strength and stability, key factors for industries prioritizing cost-effectiveness and functionality. The intrinsic design of the honeycomb pattern is not merely an aesthetic choice but a strategic enhancement that maximizes the panel’s rigidity and structural integrity.

The benefits also extend to logistics and handling, as the reduced weight simplifies transportation and installation processes. This makes honeycomb panels an attractive option for both small—and large-scale projects looking to streamline operations without compromising on quality and performance. Such efficiency translates into tangible cost savings and smoother project execution.

Strength and Durability

The robust nature of honeycomb panels offers a significant advantage in scenarios where enduring harsh environments is imperative. Their capacity to evenly distribute mechanical forces across their surface area reduces the likelihood of deformation or structural failure, extending their lifespan and reliability. This attribute is especially critical in sectors like aerospace and transportation, where safety and resilience are paramount.

Furthermore, the honeycomb structure’s ability to withstand high-pressure environments makes it suitable for applications ranging from building facades to armored vehicles. This resilience ensures that honeycomb panels maintain their form and function even under duress, affording them a competitive edge over traditional materials that may require more frequent repairs or replacements.

Lightweight Advantages in Modern Engineering

In today’s engineering landscape, reducing the weight of structures without compromising their strength is a significant goal. Honeycomb panels play a critical role in this endeavor, particularly in sectors such as aerospace, where every kilogram saved translates to improved fuel efficiency and reduced emissions. By utilizing these panels, engineers can achieve the delicate balance between maintaining structural integrity and optimizing overall weight, which is essential for sustainable innovation.

The aviation industry, in particular, reaps substantial benefits from these panels. According to a recent study, using honeycomb structures in aircraft design results in significant fuel savings and lower maintenance costs, reinforcing the tangible impact of lightweight engineering on operational efficiency and sustainability.

Versatile Applications Across Industries

From towering skyscrapers to streamlined automobiles, the application possibilities for honeycomb panels are virtually limitless. Architects appreciate their potential to create lightweight yet structurally sound designs that push the boundaries of traditional aesthetics. Meanwhile, the automotive industry benefits from the reduced vehicle weight, contributing to enhanced fuel economy and lowered emission footprints.

The panels are also popular in interior and product design, where their lightweight nature and customizable aesthetics offer a fresh perspective on design possibilities. Whether in commercial spaces or consumer products, honeycomb panels enable designers to implement creative solutions that marry form with function, exemplifying modern innovation.

Environmental Impact and Sustainability

As the global focus shifts towards sustainability, the environmental benefits of honeycomb panels take center stage. Made from recyclable materials, these panels align with environmentally-friendly practices and support circular economy principles. Their production often results in lower emissions and resource use, making them a preferred choice for projects with stringent environmental standards.

This eco-friendly attribute and its durability reduce the need for frequent replacements, which typically burden the environment through waste and emissions. The panels’ long lifespan further amplifies their sustainable credentials, allowing industries to reduce their ecological impact while maintaining high-performance standards.

The Future Outlook for Honeycomb Panels

The potential for honeycomb panels to transform engineering and architectural landscapes is vast. As technological advancements continue, these panels will likely become integral to cutting-edge projects demanding durable and environmentally responsible materials. Continued research and development will likely yield enhancements in panel performance and environmental benefits, solidifying their place as a cornerstone of modern and future infrastructure.

The strong emphasis on sustainability and efficiency points to a promising future where honeycomb panels will meet and exceed performance expectations, setting new benchmarks for quality and innovation in the construction and manufacturing sectors.